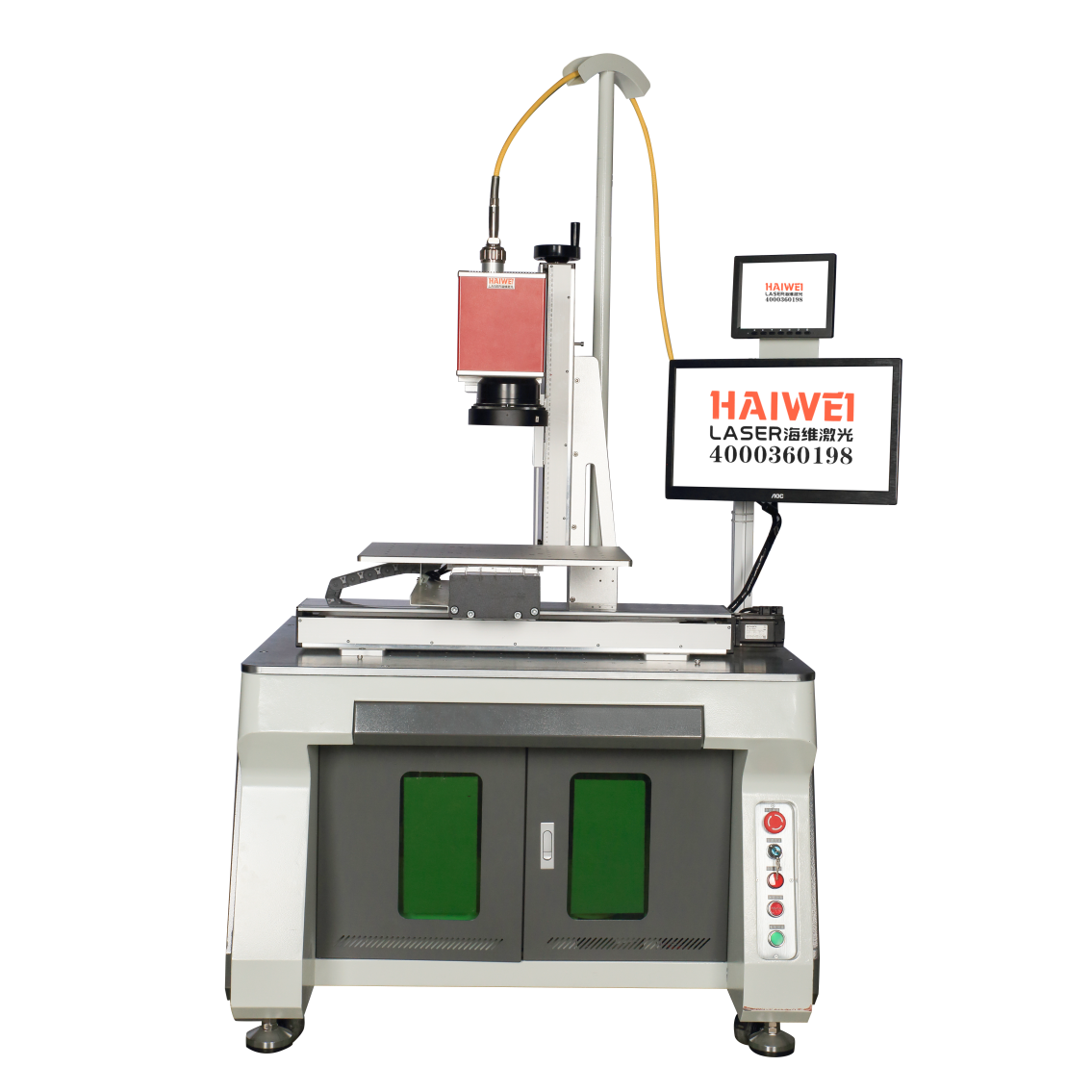

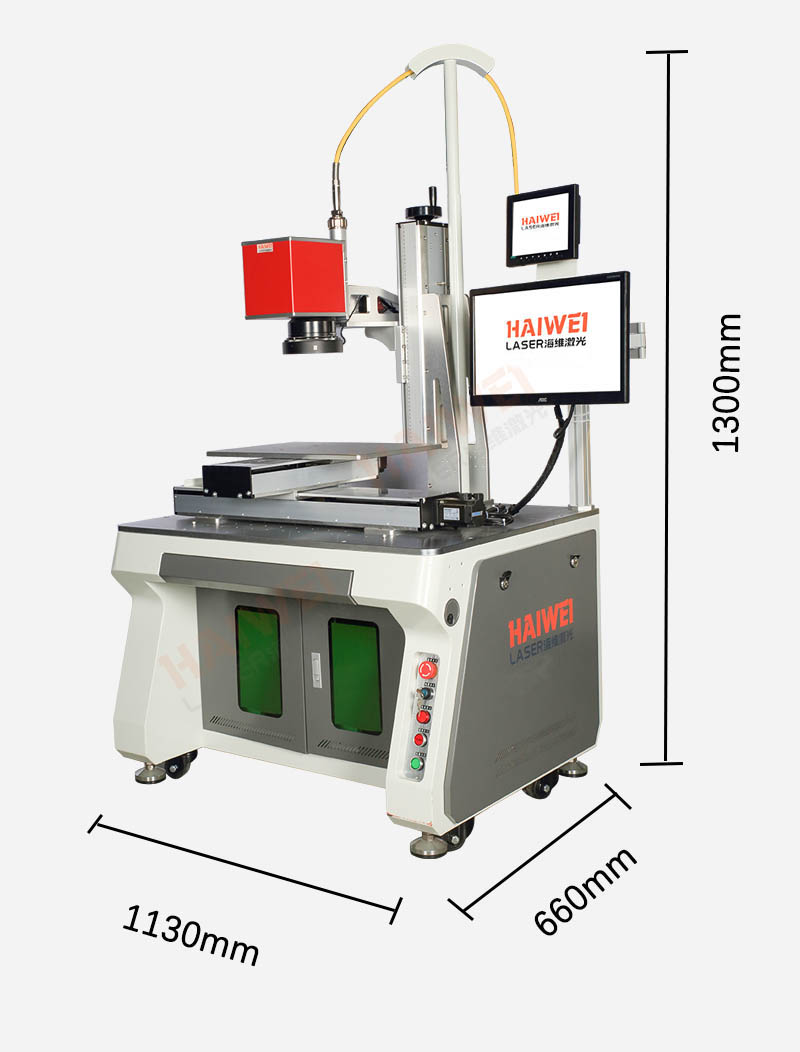

Continuous fiber laser welding machine

Other recommendations

Overview

Adopting 1000-3000 watt fiber laser with high electro-optical conversion efficiency, long laser life, intelligent operation, flexible and reliable, equipped with leading welding modules in China, to achieve more precise and perfect welding. Intelligent operation platform, more flexible, automated, and efficient. CCD LCD monitoring and inspection system can clearly observe product positioning and welding effect based on red light indication. Automated weld seam tracking system, real-time tracking of weld seam shape, timely correction of the position of the welding torch based on the condition of the weld seam, achieving precise welding and a more beautiful welding surface. The HW series exclusive patented welding technology is more suitable for welding workpieces with wider weld seams, and has a wider range of welding applications, achieving precision welding for larger workpieces, wide weld workpieces, etc.

Product features:

Intelligent operation platform, more flexible, automated, and efficient.

High cooling rate results in fine weld microstructure and good joint performance.

◆ No consumables, (small size), flexible processing, low operating costs.

The weld seam is thin, deep, has a small taper, and high precision; Smooth, flat, and aesthetically pleasing appearance.

High energy density, low heat input, small thermal deformation, narrow melting zone and heat affected zone, and deep melting depth.

CCD LCD monitoring and inspection system can clearly observe product positioning and welding effect based on red light indication.

◆ Automated weld seam tracking system, real-time tracking of weld seam shape, timely correction of the position of the welding torch based on the condition of the weld seam, achieving precise welding and a more beautiful welding surface.

The HW series exclusive patented welding technology is more suitable for welding workpieces with wider weld seams, and has a wider range of welding applications, achieving precision welding for larger workpieces, wide weld workpieces, etc.

Application scope:

Strong adaptability and wide application. Typical application areas: batteries, consumer electronics, solar panels, automotive parts, hardware and kitchenware, medical equipment, sensors, molds, jewelry, glasses, stainless steel doors and windows, and other industries.

Applicable materials:

Materials such as carbon steel, stainless steel, aluminum, copper, nickel, titanium, silver, gold, platinum, alloys, etc.

- Tel:

-

Email:

Certifications

INQUIRY